GWS TOOL GROUP BLOG

GWS Custom Drill Improves Tool Life by 100%!

This major international automotive supplier faced significant challenges related to tool life, impacting their production efficiency and causing machine downtime. GWS recreated their custom step drill to cut cycle time and overall tool cost by $240,000.[...]

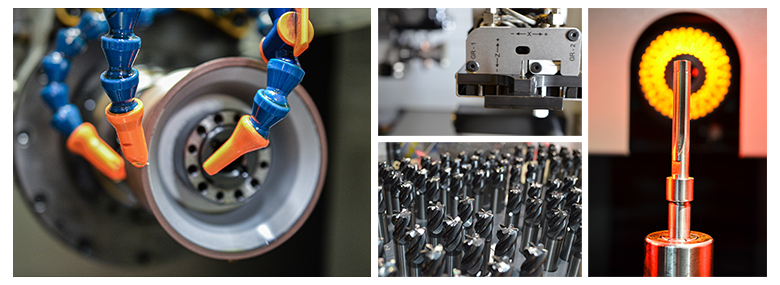

Cutting Edge Honing: Why it Matters

In the newest Manufacturing 101, we will discuss cutting edge honing and why it matters. Honing the cutting edge is a process of smoothing and refining the cutting edge of a tool. The process involves removing any irregularities or imperfections that may have occurred during the tool’s manufacturing or use. The honing process is essential […]

Employee Spotlight: Kelli Harris

Meet Kelli Harris, our Business Intelligence Manager at our GWS-IL facility in South Beloit, Illinois. Kelli first began her journey at the facility in 2005, initially drawn by a newspaper advertisement. In her 18-year tenure at GWS, Kelli has evolved into a vital asset, prominently contributing to our ERP (Enterprise Resource Planning) implementation team. […]

GWS Tool Group Embarks on a New Era: Announces Independent Division and Leadership Transition

To fortify its standing in the custom cutting tool industry, GWS is set to emerge as an autonomous division, branching out from Walter Tools, within the Sandvik Group. With fresh leadership spearheaded by a new President, our focus remains steadfast on expanding our reach in both custom and standard tooling sectors across North America. Tavares, […]

Understanding the Different Types of Carbide in Cutting Tools

In this Manufacturing 101, we will explore the different types of carbide materials used in cutting tools. Carbide cutting tools are widely used in the manufacturing industry due to their hardness, durability, and high resistance to wear. Understanding the different types of carbides and their properties can help you choose the right tool for your […]

Employee Spotlight: Lan Patthana

Meet Lan Patthana, a Quality Inspector at GWS-Batavia in Batavia, Illinois. Lan started at the facility as a part-time employee while in college, and has now been there for 34 years! Lan’s story in the cutting tool industry began as a part-time college student, seeking more stability than her job at a candy shop […]

Sharper Savings, Superior Performance: GWS Custom Tooling Drives 80% Cost Savings

A precision automotive manufacturer was facing long cycle times. GWS created a custom solution that not only saved 4 hours of cycle time but increased productivity by 25%. Overall, GWS saved this manufacturer $43,650 in total cost savings![...]

Forming Taps vs. Cutting Taps – Which One Should You Choose?

Today we will discuss the differences between forming taps and cutting taps, and which one you should choose for your application. Taps are an essential tool used in the manufacturing process to create threads in a workpiece. Understanding the differences between forming taps and cutting taps can help you make the right choice and achieve […]

Employee Spotlight: Elena Taylor

Meet Elena Taylor, our Customer Service Department Manager – Inserts and Advanced Material, from our GWS-NC location in Arden, North Carolina. Elena has been with GWS since 2021. Elena is originally from Schwabisch Hall, Germany, and came to the United States while still a university student to complete an internship for a different manufacturing […]

How Bone Screws are Made with Inserts – The Manufacturing Process

In today’s Manufacturing 101 post, we will be discussing the manufacturing process of producing bone screws using inserts. Bone screws are an essential component used in orthopedic surgeries for fixing bone fractures or in reconstructive procedures. In recent years, the use of inserts in bone screw manufacturing has gained popularity due to their efficiency and […]