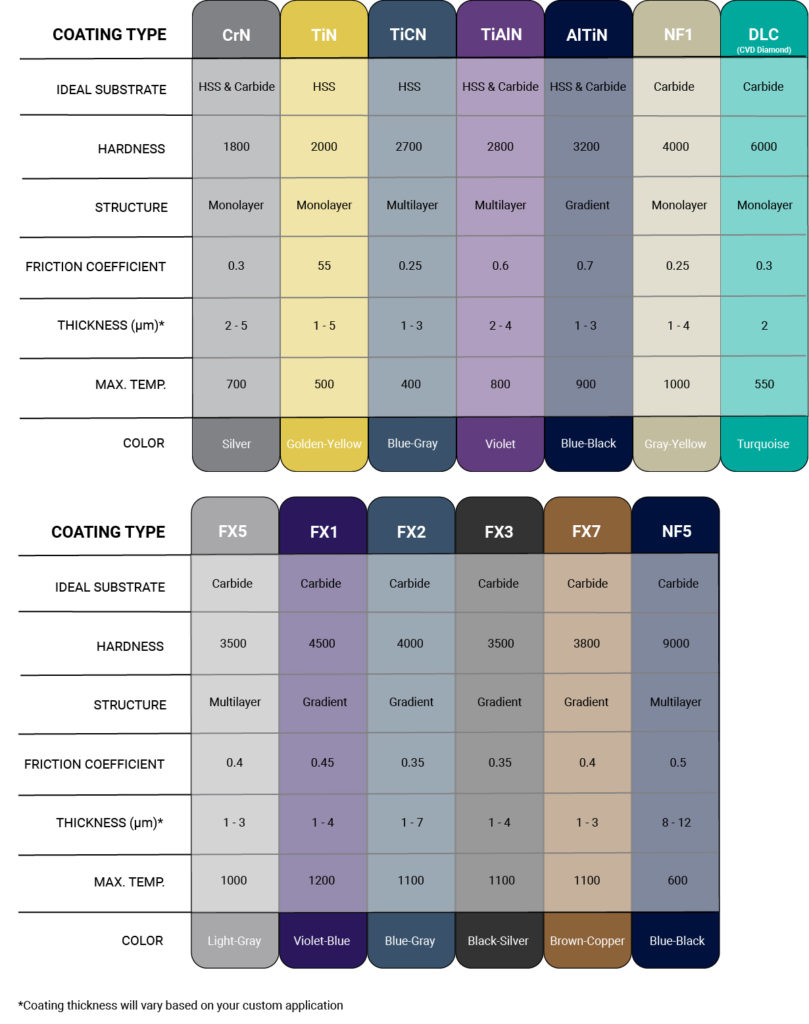

Our in-house coating facility provides fast turnaround on coated tools, extending your tool life and improving performance. Browse our available coatings below. Don’t see the one you’re looking for? Use our custom tool request form to suggest a coating for your tool.

Available Coatings

CrN

Chromium Nitride

Chromium Nitride

Ideal for non-ferrous applications like aluminum or copper. Adds wear resistance via increased hardness (1800 HV) and lubricity for extended performance and tool life.

TiN

Titanium Nitride

Titanium Nitride

General purpose coating with good adhesion add lubricity and wear resistance. Maximum service temperature of 500 degrees C and hardness of 2000 HV. Ideally suited for HSS taps, drills and end mill.

TiCN

Titanium Carbon Nitride

Titanium Carbon Nitride

Performance coating ideally suited for HSS tools, including taps, drills and end mills. Higher hardness versus TiN at 2700HV and improved coefficient of friction of 0.3.

TiAlN

Titanium Aluminum Nitride

Titanium Aluminum Nitride

Performance coating with high hardness (2800 HV) and high oxidation temperature of 800 degrees C. Ideally Suited for high speed machining operations using air or MQL coolant.

AlTiN

Aluminum Titanium Nitride

Aluminum Titanium Nitride

Performance coating with high hardness and high oxidation temperature of 800 degrees C. Ideally suited for high speed machining operations using air or MQL coolant. Increased aluminum in coating enhances heat resistance and lubricity at elevated temperatures.

NF1

PVD

PVD

This Zirconium-based coating is designed for high performance aluminum machining applications to extend tool life by increasing wear resistance and reducing BUE via an ultra-smooth coating finish.

FX5

PVD

PVD

AlTiN-based PVD nanolayer coating with high hardness (35 Gpa) and a maximum service temperature of 1000 degrees C. Ideal for holemaking and drilling operations where coolant supply is not always optimal at the cutting edge.

FX1

PVD

PVD

High performance nano composite coating with extreme high hardness and high heat resistance. For high performance milling operations in alloyed steels, hardened steels and Nickel Alloys.

FX2

PVD

PVD

High performance nano composite coating with high abrasion and heat resistance. High coating thickness possible. Especially for hobbing and forming tools.

FX3

PVD

PVD

An AlCrN-based nano composite coating that combine titanium to create a layered coating with high hardness (3000 HV) and heat resistance (800 degrees C). Performs well in wet or dry machining operations and ideal for alloyed steels, stainless steels and titanium alloys.

FX7

PVD

PVD

A high performance coating for stainless steels, hardened steels and titanium. High maximum operating temperature of 1100 degrees C and refined coating thickness ensures minimal edge rounding.

DLC

Diamond-like Carbon (CVD Diamond)

Diamond-like Carbon (CVD Diamond)

DLC is a PVD coating that offers a unique combination of high hardness and low friction coefficient with the hardness similar to diamond and the lubricity of graphite. Suited for non-ferrous materials and extends tool life versus uncoated tools by 3-5X.

NF5

CVD

CVD

Ultra-fine layered NF5 coating with sub-micron grain size for enhanced performance in non-ferrous materials including aluminum, graphite and carbon fiber reinforced plastics (CFRP).