Case Study

GWS Makes the Dream Work

Customer

A Small Commercial Aircraft Manufacturer

Part and Material

T6-6061 Aluminum front and rear cabin assembly

The Situation

A manufacturer of small commercial private aircraft had been having extreme concentricity issues when drilling and reaming two mating components for their front and rear cabin assembly. This specific application is unique because it features a 6-inch gap between the T6-6061 Aluminum cabin and the body frame of the plane. Due to the large size and shape of the parts, manual pneumatic drills were the machining method of choice, used with chuck and guide bushings, to process the two holes so they could ultimately be bolted together. The original application consisted of three separate drills to complete the finished part. Attempt after attempt was made, with repeated failure of pin gage testing. Simply put, the two mating holes were never quite right. This led to cycle times of over an hour and consistent frustration on every level.

Current Process Results

- 3 different drills needed

- Manual pneumatic drills

- Over 1 hour cycle time per piece

- Variances in between tool changes

- Extreme concentricity issues

New GWS Solution

- 2 custom tools in one

- Custom dreamer (drill/reamer)

- Improved finish

- Reduced cutting resistance

- 25 minute cycle time, 60% reduction

- Regrind available for custom tool = lower tool cost and consumption

Conclusion

Like any application, GWS starts the process with our Application Specialists listening to the customer, their problem, and experience with their test results. Taking these points into consideration, GWS specialists and engineers got together to discuss finding a solution.

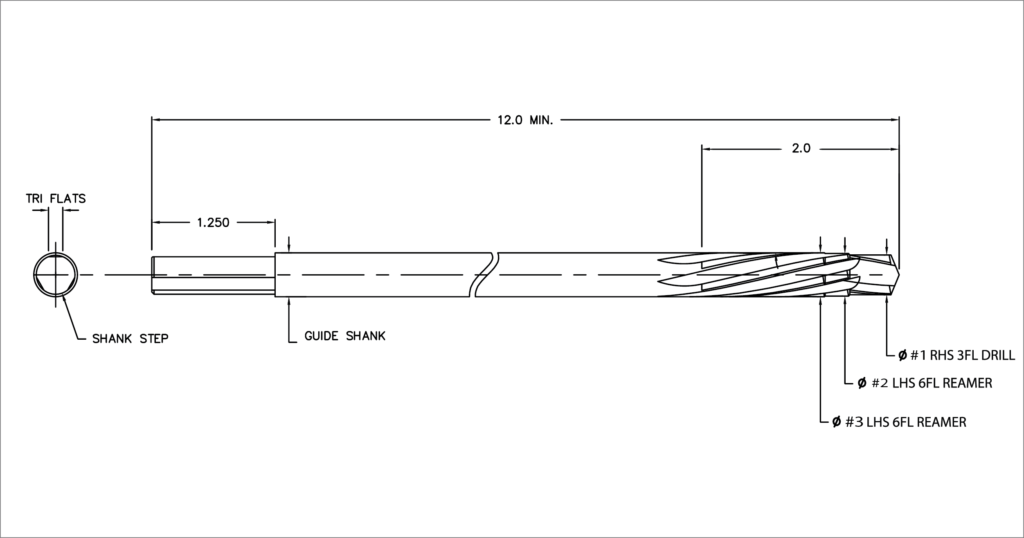

The first thought was that a standard tool would not be the solution to this difficult application. With issues of concentricity and alignment, we knew this drill had to be tailor-made to them. The custom GWS take on a dreamer (drill/reamer) was the perfect solution to their problem. A 3-flute right-hand helix drill at the front, morphing to a 2-step, 6-flute reamer on the back to produce the perfect hole in one shot.

This tool brought the application from three separate tools down to two by combining the two drilling applications into one progressive 2-step reamer. The new combination tool eliminated variances between tool changes and guide bushings while improving the finish, reducing cutting resistance, and eliminating concentricity issues. It is also noteworthy that more than a few massive headaches were cured.

This application dropped the cycle time by over 50%, from 1 hour per piece to 25 minutes. With a comprehensive regrind program, overall tool costs and consumptions were also greatly reduced. This success, accompanied by the relative ease and speed of delivery from GWS, opened this customer’s eyes to the possibilities of using custom tools from GWS Tool Group.

Interested in finding out more information about our standard and custom tools? Consider contacting the experts who make Custom Come Standard, and let us find the perfect cutting tool for you. Just send us an email at sales@gwstoolgroup.com to get started!